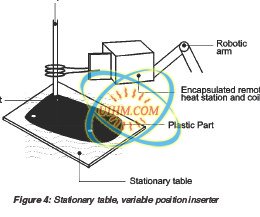

Induction Heat Staking Inserting Metal into Plastic Class:Induction Heating Tech Article

Induction Heat Staking Inserting Metal into Plastic Class:Induction Heating Tech Article Intro: Basics of Metal-to-Plastic BondingSince steel, brass and aluminum are the materials of choice for metal inserts for plastic bonding, let us look at the relative merits of each material and see how each characteristic effects the ability of the material to …

Induction Heating Billets (RCS) Class:Induction Heating Tech Article

Induction Heating Billets (RCS) Class:Induction Heating Tech Article Intro: There are three basic induction approaches to heat RCS billets: static, progressive and oscillating heating. The most popular of these is the progressive multi-stage horizontal heating system, in which billets are moved through a single or multi-coil horiz…

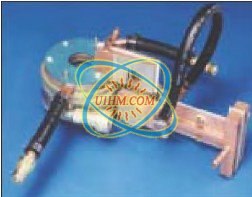

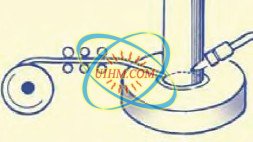

Magnetic Flux Concentrators Class:Induction Heating Tech Article

Magnetic Flux Concentrators Class:Induction Heating Tech Article Intro: Magnetic flux concentrators (also called flux intensifiers, diverters, or controllers) are made from high- permeability, low-power-loss materials. They are routinely used in induction heat treating applications (Fig. 1) in a manner similar to that of mag- …

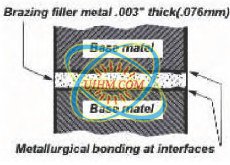

what is induction vacuum brazing Class:Induction Heating Tech Article

what is induction vacuum brazing Class:Induction Heating Tech Article Intro: Brazing especially vacuum brazing is highly sophisticated and specialized joining process as compared to welding and other conventional methods of joining. The brazing process is deployed when component joining becomes difficult by using the conventional m…

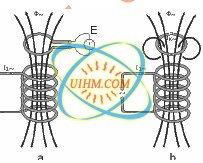

induciton heating technology review Class:Induction Heating Tech Article

induciton heating technology review Class:Induction Heating Tech Article Intro: Electromagnetic induction, simply induction, is a heating technique for electrical conductive materials (metals). Induction heating is frequently applied in several thermal processes such as the melting and the heating of metals.Induction heating has the i…

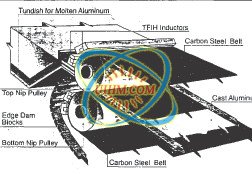

Induction Heating producing Aluminum Class:Induction Heating Tech Article

Induction Heating producing Aluminum Class:Induction Heating Tech Article Intro: Barmet Aluminum Corporation produces 300 million lbs. of aluminum sheet per year and has plants located inUhrichville, Ohio and Carson City, California. At the plants, scrap and ingots are melted in gas-fired reverberatoryfurnaces and the molten aluminum a…

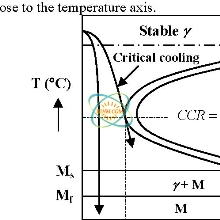

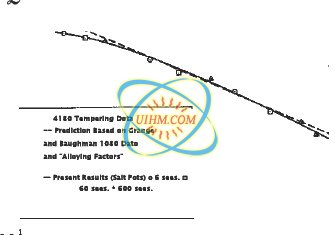

induction tempering of steel Class:Induction Heating Tech Article

induction tempering of steel Class:Induction Heating Tech Article Intro: The tempering of hardened steels is surely one of the most important of industrial heat-treating operations. For this reason, the mechanisms underlying the process as well as the effect of tempering on final mechanical properties have received wide attenti…

tubular Induction brazing wires Class:Induction Heating Tech Article

tubular Induction brazing wires Class:Induction Heating Tech Article Intro: Made from seamless tubular wire This ensures consistent flux to wire ratio and is especially important in the fabrication of pre-forms.Competitors' products are made from folded sheets and flux may be lost during fabrication or during transport.Our flux co…

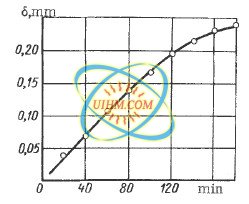

induction PLATING OF STEEL IN VACUUM Class:Induction Heating Tech Article

induction PLATING OF STEEL IN VACUUM Class:Induction Heating Tech Article Intro: We investigated chromium plating of steel heated in vacuum by high frequency induction. The chromiumplating mixture was low carbon ferroehromium. We used steel No. 10 and steel U8 in our experiments.The current source was the GL-15M 8.5 kW tube generator, …

Cadmium in silver soldering or brazing Class:Induction Heating Tech Article

Cadmium in silver soldering or brazing Class:Induction Heating Tech Article Intro: Silver (hard) soldering or brazing is a very versatile means of making joints by using a fusible alloy as a filler material between similar or dissimilar parent materials.Temperatures above 620C are applied, usually by handheld flame torch or another heati…