Induction Bonding Solar Panels

Views Send Enquiry

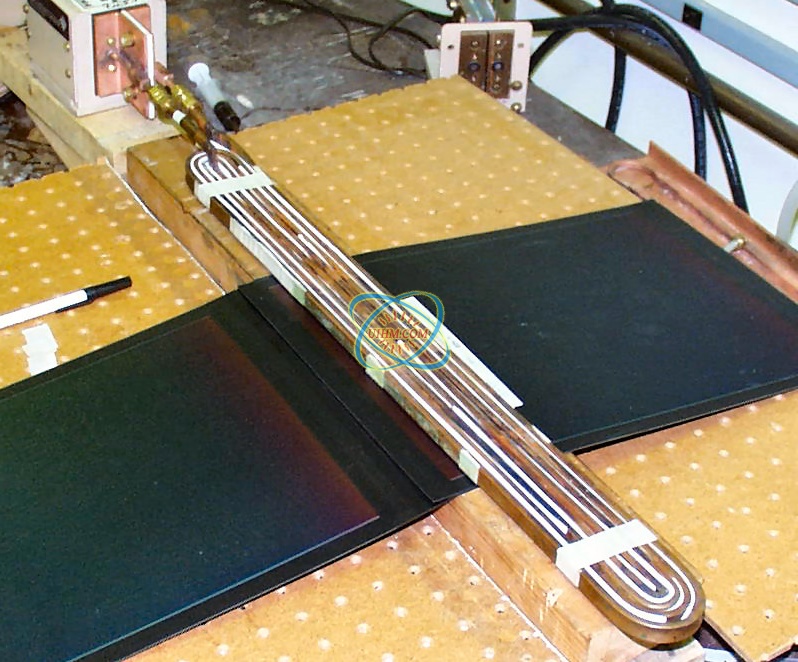

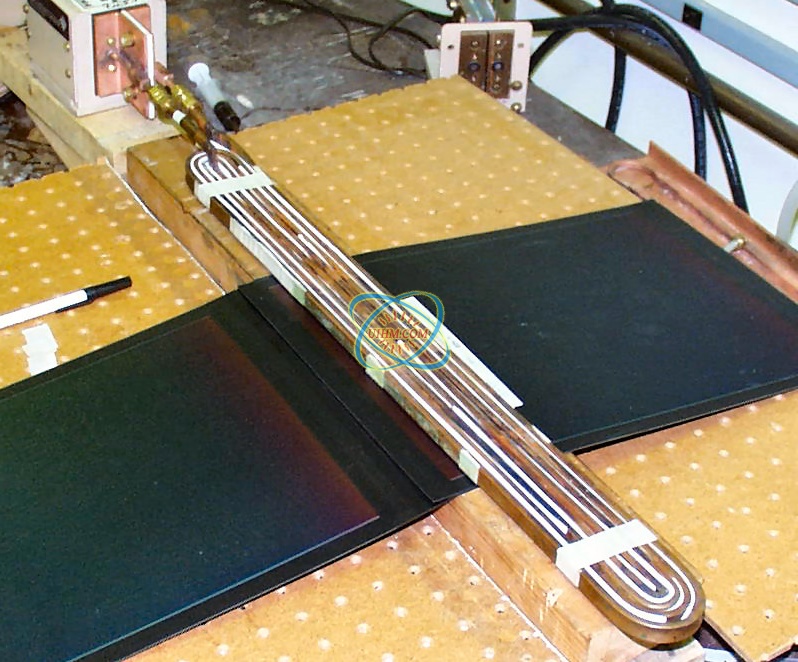

Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.

Material 3″ by 10.25″ section of a 21″ solar panel shingle

Temperature 130 ºC

Frequency 166 kHz

Equipment Power of 20KW power supply equipped with a remote heat station containing one 0.66mF capacitor. A custom-made coil: 4 turns of 1/4″ x 1/2″ rectangular copper tubing, measuring

24″ by 2 1/4″.

Process Stationary heating – with the coil located on the topside of the sample – was utilized to achieve uniform melt and adhesion.

The shingles were overlapped according to requirements and placed on wood to simulate the installation on a roofing

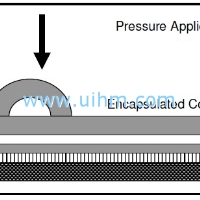

surface. In addition, pressure was applied by pressing thewater-cooled coil against the shingle to facilitate the bonding (illustration). Tests are performed at several time-voltage settings.

Results Tests resulted in excellent bond formation with the absence of encapsulant bubbling and only slight surface texture change.

Material 3″ by 10.25″ section of a 21″ solar panel shingle

Temperature 130 ºC

Frequency 166 kHz

Equipment Power of 20KW power supply equipped with a remote heat station containing one 0.66mF capacitor. A custom-made coil: 4 turns of 1/4″ x 1/2″ rectangular copper tubing, measuring

24″ by 2 1/4″.

Process Stationary heating – with the coil located on the topside of the sample – was utilized to achieve uniform melt and adhesion.

The shingles were overlapped according to requirements and placed on wood to simulate the installation on a roofing

surface. In addition, pressure was applied by pressing thewater-cooled coil against the shingle to facilitate the bonding (illustration). Tests are performed at several time-voltage settings.

Results Tests resulted in excellent bond formation with the absence of encapsulant bubbling and only slight surface texture change.

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Newest Comment

No Comment

Post Comment