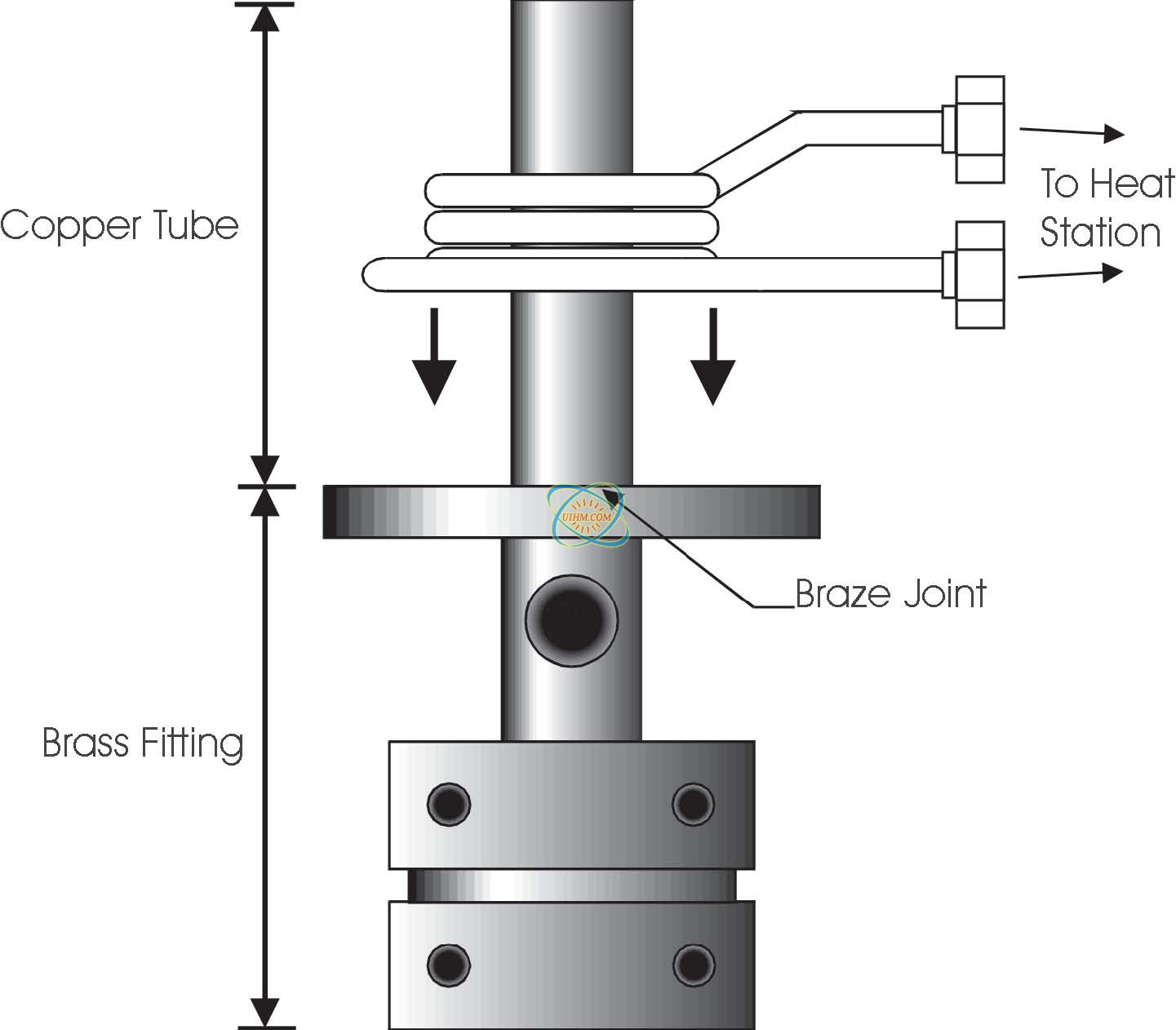

Induction Braze Copper Tube to Brass Fitting

Views Send Enquiry

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190°F, but the parts need to be kept below 1300°F. The parts need to be processed at a rate of 175 to 200 per hour which translates into 18 seconds of heating time per part.

Material Copper Tubing Measuring 0.5″ OD and 2″ Long, Brass fitting, Braze Preform, No Flux.

Temperature Above 1190°F but not to exceed 1300°F

Frequency 133 kHz

Equipment Power of 6kW output solid state induction heating power supply with three (3) busses, eight (8) capacitors totaling 0.66 μF, and a unique four turn helical coil.

Process Power of 6KW output solid state power supply along with a unique four turn helical coil were used to achieve the following results.

Results • The requested atmosphere was provided under a bell jar by supplying 95% Nitrogen/5%Hydrogen at a rate of 25-30 cfh.

• A heating cycle of only 10 seconds was necessary to attain sufficient braze flow which surpasses the required limit of 18 seconds

Material Copper Tubing Measuring 0.5″ OD and 2″ Long, Brass fitting, Braze Preform, No Flux.

Temperature Above 1190°F but not to exceed 1300°F

Frequency 133 kHz

Equipment Power of 6kW output solid state induction heating power supply with three (3) busses, eight (8) capacitors totaling 0.66 μF, and a unique four turn helical coil.

Process Power of 6KW output solid state power supply along with a unique four turn helical coil were used to achieve the following results.

Results • The requested atmosphere was provided under a bell jar by supplying 95% Nitrogen/5%Hydrogen at a rate of 25-30 cfh.

• A heating cycle of only 10 seconds was necessary to attain sufficient braze flow which surpasses the required limit of 18 seconds

Braze-Copper-Tube

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

UHF handheld induction heater for brazing copper

UHF handheld induction heater for brazing brass

handheld induction coil for soldering brass

handheld induction coil for brazing brass

induction brass soldering for refrigerator pipes

induction brass soldering with D80mm red copper with 60% silver solder paste

induction brass soldering pipes for chiller

induction brass soldering for multi pipes

Newest Comment

No Comment

Post Comment