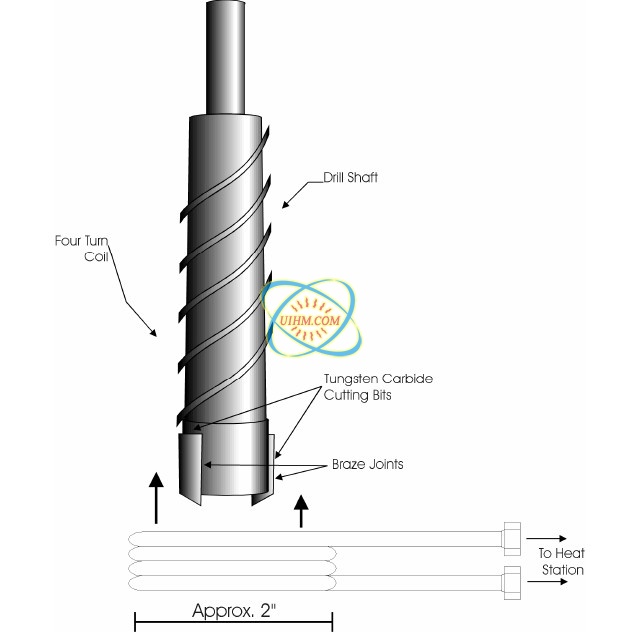

Induction Brazing Carbide Tips on Drill Bits

Views Send Enquiry

Objective To braze carbide cutting tips to drill bits ranging in size from 0.5″ to 1.5″ in diameter. The brazing takes place at 1900°F and is presently done in 11 seconds for the 0.5″ diameter bit and 39 seconds for the 1.5″ diameter bit. Customer goals include decreasing the brazing times, especially for the larger drill bits, and repeatability must be adequate. Heating can be done using a helical coil since the drill bits are presently front-loaded into a double turn helical coil.

Material 4140 Leaded Steel Twist Drill Shanks and Tungsten Carbide Tips with Harris 870 Braze and Tricon Gray Flux.

Temperature 1900°F

Frequency 106 kHz

Equipment Power of 45kW output solid-state induction power supply with eight (8) capacitors and 5:3 RF transformer ratio.

Process The Power of 45kW solid state induction power supply along with specifically designed coils and laboratory research were combined to produce the following results:

· A brazing temperature of 1900°F was reached through the use of a unique 4 turn helical coil. Different coils were

designed for each size drill bit to maximize efficiency through coupling.

· Quality braze joints were achieved due to the uniform heat pattern created by the induction field.

Results Heating times were met and surpassed. For the 0.5″ drill bit 11 seconds was required to reach 1900°F while 32 seconds was necessary for the 1.5″ drill bit. These results indicate a decrease in heating time of 7 seconds for the 1.5″ drill bit while retaining quality and repeatability

Material 4140 Leaded Steel Twist Drill Shanks and Tungsten Carbide Tips with Harris 870 Braze and Tricon Gray Flux.

Temperature 1900°F

Frequency 106 kHz

Equipment Power of 45kW output solid-state induction power supply with eight (8) capacitors and 5:3 RF transformer ratio.

Process The Power of 45kW solid state induction power supply along with specifically designed coils and laboratory research were combined to produce the following results:

· A brazing temperature of 1900°F was reached through the use of a unique 4 turn helical coil. Different coils were

designed for each size drill bit to maximize efficiency through coupling.

· Quality braze joints were achieved due to the uniform heat pattern created by the induction field.

Results Heating times were met and surpassed. For the 0.5″ drill bit 11 seconds was required to reach 1900°F while 32 seconds was necessary for the 1.5″ drill bit. These results indicate a decrease in heating time of 7 seconds for the 1.5″ drill bit while retaining quality and repeatability

Brazing-Carbide-Tips

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment