Induction Fusing the butt joint

Views Send Enquiry

Objective: Fuse elastomer (TPE) tubes together in two ways, as a butt joint and as a overlap joint.

Material: PeBax tubing 3/16” (4.76) OD, 1/8” (3.18 mm) ID and slightly larger

Stainless steel Teflon coated mandrel 1/8” (3.18 mm) diameter

Temperature: 350 ºF (177 ºC)

Frequency: 352 kHz

Equipment • Power of 6kW induction heating system, equipped with a remote workhead containing two (2) .33μF capacitors (for a total of .66 μF).

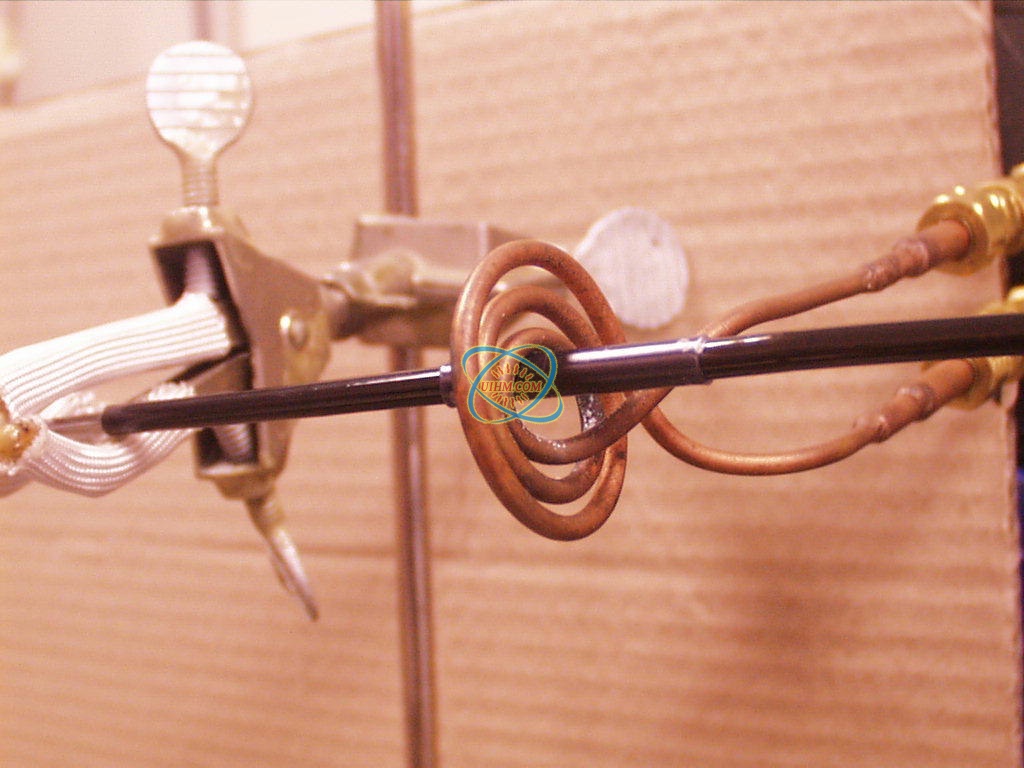

• Induction heating coils designed and developed specifically for this application.

Process For the butt joint, two tubes of the same diameter with differing degrees of hardness are used. The tubes are slipped onto the Teflon coated mandrel and a short length of shrink tubing is placed over the tubes. Hot air is blown over the shrink tubing to gently heat it. The assembly is placed in the center of a threeturn

pancake coil and heated for 8 seconds. For the overlap joint, the two tubes have different diameters.

The smaller diameter tube is placed over the mandrel first and then the larger diameter tube is slipped over it. A length of shrink tubing is placed over the assembly. Hot air is blown over the shrink tubing to gently heat it. A nine-turn helical coil is used to fuse the complete assembly together.

Results/Benefits Advantages of induction heating are:

• Heating of the mandrel is from the inside out providing a smooth finish on the outside of the assemblies.

• Precise, repeatable application of heat.

• Ambient temperature factors do not affect the process

• No over heating

Fusing the butt joint

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction jointing SS steel pipes

induction jointing SS steel parts

induction jointing brass parts

induction jointing seamless steel tube by 500KHz UHF induction heater

induction jointing wire connector by ultra high frequency induction heater

induction jointing stainless pipeline

induction jointing stainless connectors

induction jointing stainless connector

Newest Comment

No Comment

Post Comment