Induction Heating Technology in aerospace

Views Send Enquiry

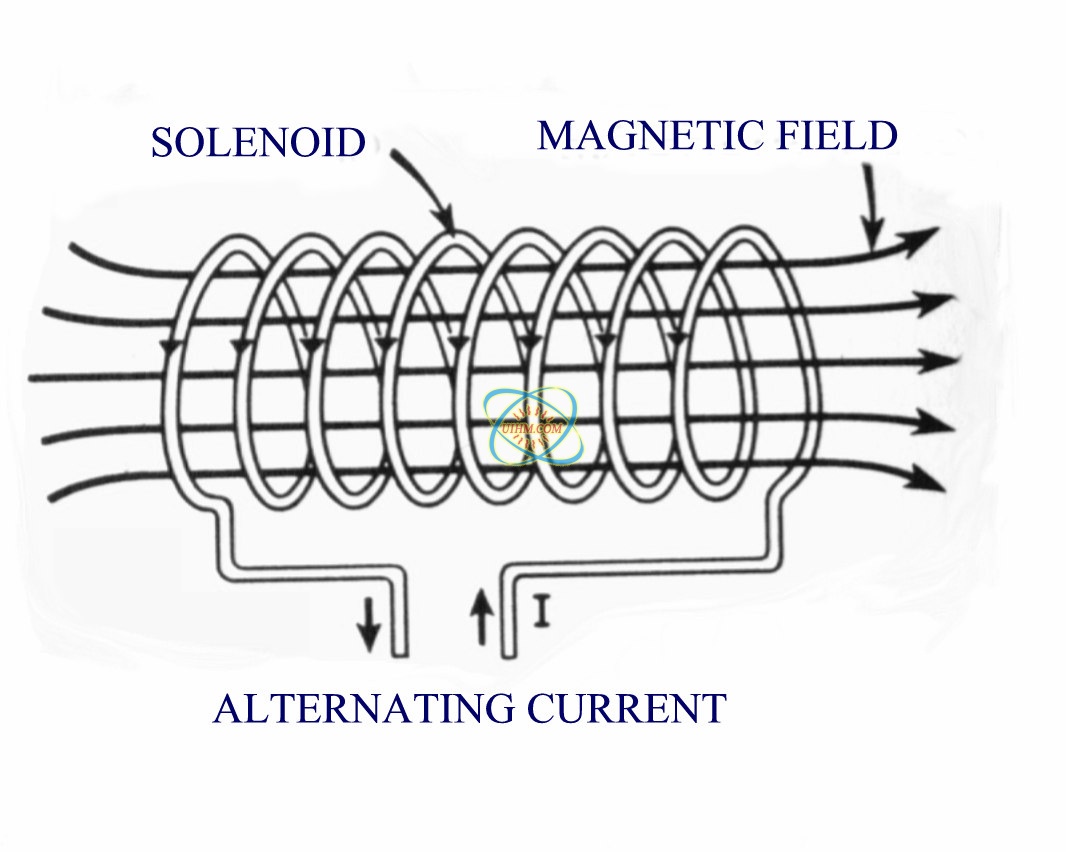

The purpose of this Tech Note is to demonstrate the advantages of Induction Heating technology like new Nova Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a crucial difference in running a specific process or application successfully. Today, Induction Heating systems are known worldwide for their speed, reliability and consistency. The new Nova Star technology advances the industry standard for induction heating performance to a new level of costeffective precision.Among the many advantages of the new technology, this document will focus on six: rapid digital tuning, advanced microprocessor control, high frequency operation and closed loop temperature control, as well as the RS-485 interface and flexible remote heat station which are standard with every Nova Star power supply.

The purpose of this Tech Note is to demonstrate the advantages of Induction Heating technology like new Nova Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a crucial difference in running a specific process or application successfully. Today, Induction Heating systems are known worldwide for their speed, reliability and consistency. The new Nova Star technology advances the industry standard for induction heating performance to a new level of costeffective precision.Among the many advantages of the new technology, this document will focus on six: rapid digital tuning, advanced microprocessor control, high frequency operation and closed loop temperature control, as well as the RS-485 interface and flexible remote heat station which are standard with every Nova Star power supply.

In the first section, Nova Star’s rapid digital tuning and high frequency operating range produce faster

throughput and increased production rates in an annealing process for copper crimp connectors. Next, the new technology’s high frequency operation allows induction heating to be used for brazing miniature diamond tips on cutting tools. The Nova Star standard RS-485 interface allows the user to download process data into a computer for statistical process control. The epoxy curing process described in the third section illustrates the benefits of this feature. The next section shows how the Nova Star remote heat station, which can be located up to 200 ft. away from the power supply, offers significant advantages for a conveyor line manufacturing operation. Finally, the fifth section illustrates how closed loop temperature control improves a tempering process for steel punches.

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction heating round steel plate edge

induction heating rocket parts

induction tempering aircraft parts

induction heating graphite rod by UHF machine

induction heating graphite by UHF machine with big induction coils

vacuum induction heating for crystal growth

induction heating for SRBM (short-range ballistic missile) by DSP air cooled induction heater

induction heating for crystal growth

Newest Comment

No Comment

Post Comment