Induction Heating multi wire bundles of rotor with different shape induction coils

Views Send Enquiry

Objective • Heating the ends of mult wires on a starter motor to remove the electrical varnishes

Material Starter motor with multi wire bundles, each wire consists of 3 wires 0.04” (1.0mm) diameter each

Temperature 1202 ºF (650 ºC)

Frequency• 300 kHz

Equipment • Power of 20kW (UM-20AB-UHF) induction heating system, equipped with a remote workhead containing two 0.5μF capacitors for a total of 0.25 μF.

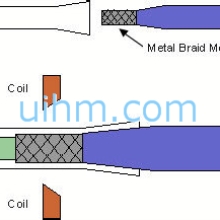

• An induction heating coil, designed and developed specifically for this application.

Process A six position coil with three turn helical coils at each position is used to simultaneously heat 0.8” (20mm) length at the end of each copper wire bundle for 2~10 seconds to burn off the electrical varnish.

Results Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing.

• Multi-position coil provides simultaneous heating for quicker production times.

• Complete removal of varnish improves electrical performance of connections.

• Even distribution of heating.

Induction Heating multi wire bundles of rotor with a cambered induction coil

Induction Heating multi wire bundles with a cambered induction coil

Induction Heating 3 wire bundles with a 3 heads induction coil

Induction Heating 3 wire bundles of rotor with a 3 heads induction coil

Induction Heating 3 wire bundles of motor with a 3 heads induction coil

PDF: Induction Heating multi wire bundles of rotor with different shape induction coils

Related Content

induction heating steel plate by pancake induction coil

induction heating steel knife

induction heating steel pipes by water cooled flexible induction coil and 120KW RF induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating inner surface

induction heating steel plate

induction heating stator frame

induction heating graphite mould

Hot

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

Induction heating for Plastic Reflow With Catheter Tubing

U shape induction coil for heating hole

induction heating steel rod with double coils

Newest Comment

No Comment

Post Comment