Induction hardening gear Class:Induction Heating Tech Article

Induction hardening gear Class:Induction Heating Tech Article Intro: In recent years, gear manufacturers have gained additional knowledge about how technology can be used to produce quality parts. The application of this knowledge has resulted in gears that are quieter, lighter, and lower cost, and have an increased load-ca…

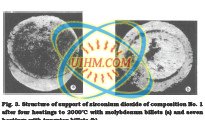

MELT REFRACTORY METALS WITH INDUCTION HEATING Class:Induction Heating Tech Article

MELT REFRACTORY METALS WITH INDUCTION HEATING Class:Induction Heating Tech Article Intro: In the Ail-Union Scientific-Research Tube Institutes industrial induction electric furnaces heated to 2000-2300C, cylindrical billets of high-melting alloys are placed on refractory supports. To select materials for the supports which do not react with mol…

Induction heating for surface triggering styrene polymerization Class:Induction Heating Tech Article

Induction heating for surface triggering styrene polymerization Class:Induction Heating Tech Article Intro: Titanium and its alloys present high interests for technological applications due to their high resistance corrosion, mechanical properties and biocompatibility [1-5]. For example, titanium is largely used as orthopedic metallic implant [6]. In addition, T…

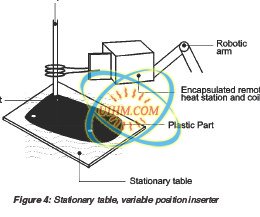

Induction Heat Staking Inserting Metal into Plastic Class:Induction Heating Tech Article

Induction Heat Staking Inserting Metal into Plastic Class:Induction Heating Tech Article Intro: Basics of Metal-to-Plastic BondingSince steel, brass and aluminum are the materials of choice for metal inserts for plastic bonding, let us look at the relative merits of each material and see how each characteristic effects the ability of the material to …

Induction Heating Billets (RCS) Class:Induction Heating Tech Article

Induction Heating Billets (RCS) Class:Induction Heating Tech Article Intro: There are three basic induction approaches to heat RCS billets: static, progressive and oscillating heating. The most popular of these is the progressive multi-stage horizontal heating system, in which billets are moved through a single or multi-coil horiz…

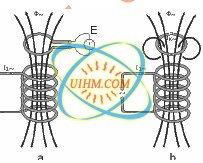

Magnetic Flux Concentrators Class:Induction Heating Tech Article

Magnetic Flux Concentrators Class:Induction Heating Tech Article Intro: Magnetic flux concentrators (also called flux intensifiers, diverters, or controllers) are made from high- permeability, low-power-loss materials. They are routinely used in induction heat treating applications (Fig. 1) in a manner similar to that of mag- …

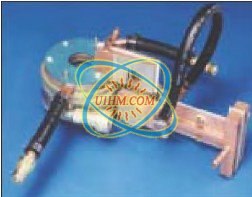

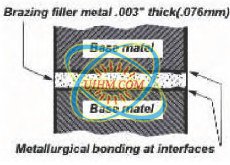

what is induction vacuum brazing Class:Induction Heating Tech Article

what is induction vacuum brazing Class:Induction Heating Tech Article Intro: Brazing especially vacuum brazing is highly sophisticated and specialized joining process as compared to welding and other conventional methods of joining. The brazing process is deployed when component joining becomes difficult by using the conventional m…

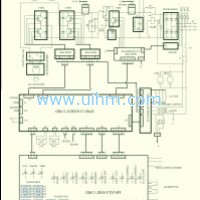

induciton heating technology review Class:Induction Heating Tech Article

induciton heating technology review Class:Induction Heating Tech Article Intro: Electromagnetic induction, simply induction, is a heating technique for electrical conductive materials (metals). Induction heating is frequently applied in several thermal processes such as the melting and the heating of metals.Induction heating has the i…

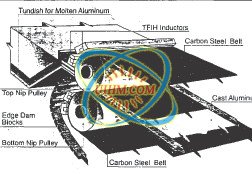

Induction Heating producing Aluminum Class:Induction Heating Tech Article

Induction Heating producing Aluminum Class:Induction Heating Tech Article Intro: Barmet Aluminum Corporation produces 300 million lbs. of aluminum sheet per year and has plants located inUhrichville, Ohio and Carson City, California. At the plants, scrap and ingots are melted in gas-fired reverberatoryfurnaces and the molten aluminum a…

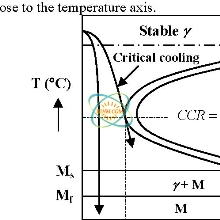

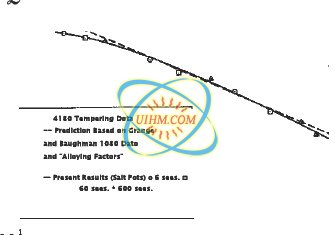

induction tempering of steel Class:Induction Heating Tech Article

induction tempering of steel Class:Induction Heating Tech Article Intro: The tempering of hardened steels is surely one of the most important of industrial heat-treating operations. For this reason, the mechanisms underlying the process as well as the effect of tempering on final mechanical properties have received wide attenti…