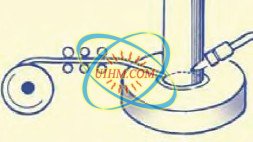

tubular Induction brazing wires Class:Induction Heating Tech Article

tubular Induction brazing wires Class:Induction Heating Tech Article Intro: Made from seamless tubular wire This ensures consistent flux to wire ratio and is especially important in the fabrication of pre-forms.Competitors products are made from folded sheets and flux may be lost during fabrication or during transport.Our flux cor…

induction PLATING OF STEEL IN VACUUM Class:Induction Heating Tech Article

induction PLATING OF STEEL IN VACUUM Class:Induction Heating Tech Article Intro: We investigated chromium plating of steel heated in vacuum by high frequency induction. The chromiumplating mixture was low carbon ferroehromium. We used steel No. 10 and steel U8 in our experiments.The current source was the GL-15M 8.5 kW tube generator, …

Cadmium in silver soldering or brazing Class:Induction Heating Tech Article

Cadmium in silver soldering or brazing Class:Induction Heating Tech Article Intro: Silver (hard) soldering or brazing is a very versatile means of making joints by using a fusible alloy as a filler material between similar or dissimilar parent materials.Temperatures above 620C are applied, usually by handheld flame torch or another heati…

HARDENING AND TEMPERING OF TOOL AND DIE STEELS Class:Induction Heating Tech Article

HARDENING AND TEMPERING OF TOOL AND DIE STEELS Class:Induction Heating Tech Article Intro: Tool and die steels are covered in BS 4659:1989,although both American nomenclature and a variety of trade names are also in use. Available in high-quality grades, these specifically-designed steels can be grouped broadly according to their intended applic…

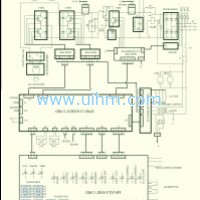

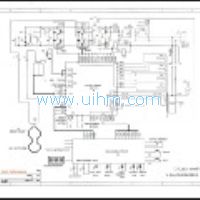

UM-25 Series Circuit Class:Induction Heating Tech Article

UM-25 Series Circuit Class:Induction Heating Tech Article Intro: UM-25 Series Circuit can also match UM-30,UM-40,UM-60 Series HF,RF machines.

induction Vacuum Brazing Class:Induction Heating Tech Article

induction Vacuum Brazing Class:Induction Heating Tech Article Intro: 5. KEY PARAMETERS OF BRAZINGThe quality of brazed joint depends strongly on the combination of filler and base materials and the processing conditions that are used. Other factors which influence the joints are condition of the solid surfaces i.e. nature o…

Theory of Heating by Induction Class:Induction Heating Tech Article

Theory of Heating by Induction Class:Induction Heating Tech Article Intro: Induction Heating was first noted when it was found that heatwas produced in transformer and motor windings, as mentioned in theChapter “Heat Treating of Metal” in this book. Accordingly, the theory ofinduction heating was studied so that motors and tran…

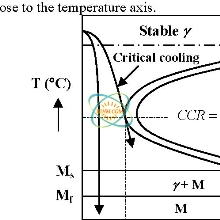

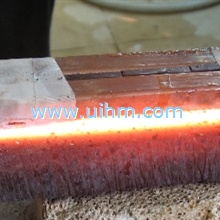

Surface Hardening of Steels Class:Induction Heating Tech Article

Surface Hardening of Steels Class:Induction Heating Tech Article Intro: Selective hardening is applied because of one or more of the following reasons:(1) Parts to be heat-treated are so large that conventional furnace heating and quenching becomeimpractical and uneconomical - examples are large gears, large rolls and dies;(2)…

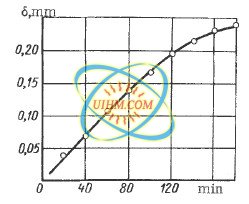

INDUCTION SURFACE HARDENING OF STEEL Class:Induction Heating Tech Article

INDUCTION SURFACE HARDENING OF STEEL Class:Induction Heating Tech Article Intro: High-level surface heating of a thermo technically massive body, when the cooling of the surface to be hardened happens due to abstraction of heat into the body so that the hardening medium is not required, is of both practical and theoretical interest. Ti…

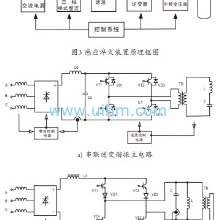

Induction Heating System Topology Review Class:Induction Heating Tech Article

Induction Heating System Topology Review Class:Induction Heating Tech Article Intro: All IH (induction heating) applied systems are developed using electromagnetic induction whichwas first discovered by Michael Faraday in 1831. Electromagnetic induction refers to the phenomenonby which electric current is generated in a closed circuit by t…